Welcome to Associated Wire Rope & Rigging .

Ropeblock Technical Catalog

Comprehensive specifications for world-class crane blocks, overhaul balls, and sheaves trusted by global OEMs for precision lifting.

Sea-Link Product Guide

Explore our diverse range of rigging solutions for construction, mining, and maritime applications, engineered for durability and versatility.

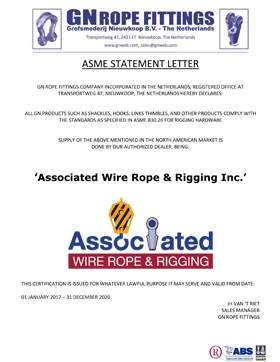

GN Rope Fittings Catalog

Detailed technical data for high-capacity forged hardware and polar-rated shackles designed for the most demanding offshore environments.

ASME B30 Compliance & Certification Guide

Essential documentation and safety guidelines ensuring your rigging operations meet the highest industry standards for zero-failure performance.

Our Benefit

Always Powering Your Business For Over 30 Years

01

Complete Engineering & Dimensional Data

Gain access to detailed technical drawings, weight specifications, and precise measurements for over 10,000 components, ensuring perfect fitment for your rigging designs.

02

Certified ASME B30 Compliance

Every catalog is structured around industry safety standards. Ensure your project meets ASME B30.26 and OSHA requirements by utilizing our verified Working Load Limit (WLL) charts.

03

High-Capacity Heavy Lift Specs

Explore technical data for the industry’s largest hardware, including GN forged shackles with capacities up to 3,000 tons, specifically designed for offshore and heavy civil applications.

04

Severe Environment & Polar Ratings

Identify hardware engineered for extreme conditions. Our catalogs highlight Polar-Rated products and specialized metallurgical finishes capable of performing in the world’s most severe climates.

05

OEM-Grade Component Listings

Access the same technical specifications used by global crane manufacturers like Terex, Manitowoc, and Liebherr. Download the primary source for original equipment replacement and upgrades.

06

Direct North American Availability

Unlike generic global catalogs, these resources represent our active North American stocking inventory, meaning the specifications you find are supported by our Los Angeles logistics center.

Work Process

Project Implementation Process

Work Process

01

Step

Technical Catalog Review & Consultation

Define. Compare. Select. Begin by utilizing our comprehensive digital catalogs to identify the specialized hardware your project requires. Our technical team is available to help you navigate complex dimensional data, Working Load Limits (WLL), and material grades to ensure the selected components align perfectly with your engineering requirements.

02

Step

Custom Quotation & Inventory Strategy

Maximize. Scale. Program. Once specifications are finalized, we develop a commercial and logistical strategy tailored to your volume. Whether you require a single critical block or a factory-direct container drop-shipment, we provide transparent pricing and inventory programs—including group shipments from our Los Angeles hub—to keep your project on budget.

03

Step

Certification & Quality Compliance

Verify. Document. Secure. Before a single component leaves our logistics center, we ensure all mandatory documentation is in order. This includes verifying ASME B30 compliance, Polar-rated safety certificates, and metallurgical test reports. We treat compliance as a non-negotiable step to guarantee the safety of your site operations.

04

Step

Expedited Fulfillment & Implementation

Deliver. Support. Succeed. Your certified rigging hardware is dispatched through our North American distribution network, ensuring it arrives on-site ready for deployment. Our partnership doesn't end at delivery; we provide ongoing technical support to ensure your project moves from the planning phase to a successful, safe, and high-performance reality.

Have any Question?

The point of using Lorem Ipsum is that it has more-or-less packages normal point of using.